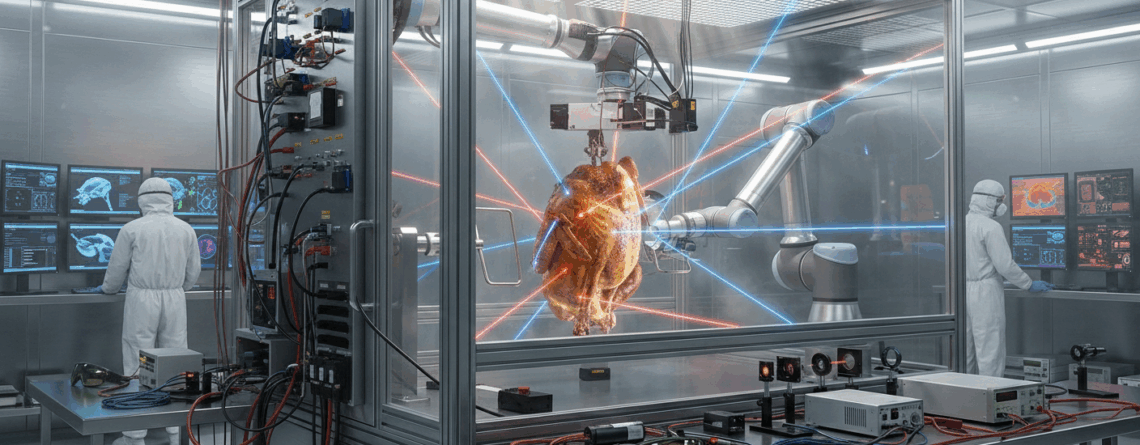

How to Cook a Turkey with Lasers (A Questionable but Glorious Lab Protocol)

Power Technology, Inc.2025-11-26T12:08:10-06:00How to Cook a Turkey with Lasers (A Questionable but Glorious Lab Protocol)

The only bird that arrives at the table pre-photonically tenderized—straight from the R&D department.

Prep time: 4–6 hours (plus 18 months of permitting)

Cook time: 3 hours 12 minutes ± 3 seconds

Yield: 12 servings or one very impressive patent filing

Difficulty: ★★★★★ (PhD in optics required; corner office optional, but helps with the expense reports)

Total Equipment Cost: $258,047

Somewhere between a Thanksgiving recipe and a directed-energy test plan lies this experiment: using industrial and research-grade lasers to roast a turkey with obscene levels of precision. Do not try this at home (or in your lab) unless your risk tolerance is measured in kilowatts.

Ingredients:

-

1 × whole turkey, 5–6 kg, preferably free-range — $45

(The protein matrix for our thermal diffusion experiment; its high water content (~70%) absorbs laser energy via vibrational modes, enabling Beer–Lambert decay for controlled volumetric heating.) -

1 × 808 nm fiber laser, 1000 W continuous wave — $42,000

(Near-infrared source tuned to water's overtone absorption peak for ~2 mm penetration depth; delivers bulk energy flux of ~1 MJ/m² per pass, driving Fourier-number-limited conduction to the turkey's core without ablating the surface.) -

1 × 445 nm blue diode laser module, 60 W — $1,800

(Shorter wavelength for shallower ~1 mm penetration in myoglobin-rich tissues; provides initial "pre-heat" layer to minimize thermal gradients, reducing ΔT by ~20% per lab models and helping prevent raw pockets.) -

1 × 10.6 µm CO2 laser, 150 W sealed tube with RF excitation — $28,000

(Mid-infrared for surface-only absorption (penetration <0.1 mm); triggers Maillard reactions at 140–165 °C via localized pyrolysis of amino acids, yielding that golden crust without polycyclic aromatic hydrocarbon formation from charring.) -

2 × high-speed galvanometric scan heads, 30 mm aperture, with f-theta lenses — $19,000 each ($38,000 total)

(Raster the beams at 400–1200 mm/s in trochoidal or Lissajous patterns; flattens the Gaussian beam profile over the turkey's ~0.5 m² surface area, ensuring uniform irradiance of 0.7–2.7 MW/m² averaged to avoid hotspots exceeding 200 °C.) -

1 × 6-axis industrial robotic arm — $68,000

(Manipulates the turkey in 3D space for omnidirectional exposure; inverse kinematics solve for paths maintaining focal distance at 150 mm, compensating for thermal expansion (α ≈ 10−5 K−1) to keep alignment within 0.5 mm tolerance.) -

1 × water chiller, 5 kW capacity — $4,200

(Thermoelectric cooling for laser diodes and optics; maintains junction temps <40 °C to prevent beam quality degradation (M² <1.1) and wavelength drift, which could shift absorption efficiency by ~15%.) -

1 × thermal imaging camera with 30 Hz streaming — $11,000

(Infrared pyrometry for closed-loop feedback; maps surface emissivity (ε ≈ 0.95 for poultry) to detect hotspots, triggering PID modulation of laser duty cycle (τ = 1–10 ms pulses) for isothermal control.) -

4 × 99.99% gold-coated off-axis parabolic mirrors, 4-inch — $1,200 each ($4,800 total)

(Reflects beams with >99% efficiency across wavelengths; off-axis design avoids central obstruction, directing parallel rays to the galvo focus for collimated delivery without spherical aberration.) -

1 × Class IV laser safety enclosure, 2 m × 2 m × 2.5 m, with interlocked polycarbonate windows tinted for 808/445/10.6 µm — $38,000

(Containment for ~1.2 kW total output; interlocks enforce ANSI Z136.1 compliance, dumping power to a beam block if doors open, helping prevent retinal injury at ~10−3 J/cm² exposure.) -

1 × argon gas cylinder, ultra-high purity — $380 + refills

(Inert purge at 5 L/min flow; displaces O2 to inhibit oxidation and plasma formation during high-irradiance scans, keeping reaction kinetics to pure photothermal heating.) -

1 × single-board computer running custom Python + laser control software + PID temperature control — $120

(Edge computing for real-time orchestration; integrates galvo drivers via USB, robot via Ethernet/IP, and thermal camera via GigE—processes 30 fps thermals with Kalman filtering for noise-reduced temperature profiles.) -

1 × uninterruptible power supply, 20 kVA — $6,800

(Battery-backed AC for 208 V / 3-phase draw; bridges surges that could desync phase-locked RF excitation in the CO2 tube, avoiding mode hopping and unstable output.) -

1 × fire-suppression system, CO2 dump rated for 100 kW thermal events — $14,000

(Automated quench for runaway exotherms; deploys if integrated thermocouples detect >250 °C, cooling via latent heat of sublimation (ΔH ≈ 573 kJ/kg) to avert a full-blown conflagration.) -

Salt, pepper, and a single sprig of rosemary — $2

(Seasoning for the illusion of normalcy; the lasers can sublimate the herbs at ~300 °C, infusing trace volatiles before they're ionized—bonus flavor chemistry.)

Total equipment cost: ~$258,000 (street price, no volume discount)

Total cost if you already own a defense contractor: $47 (just grab a turkey and repurpose the directed-energy prototype).

Special Equipment

- FDA laser product registration (Class IV)

- Lab safety committee waiver (unsigned, but we'll forge it later)

- One very understanding boss who thinks “interdisciplinary research” includes Thanksgiving dinner

Setup: Building Your Unsanctioned Lab Death Ray Oven

Assembling this photonic poultry roaster is like constructing a mini particle accelerator on the cleanroom floor—equal parts mad science and impending IACUC violation.

Start with the enclosure: bolt the 2 × 2 × 2.5 m aluminum frame to the lab's anti-vibration optical table (Newport RS2000, because that undergrad's footsteps at 5 Hz will jitter your beam like a bad caffeine habit).

Install the tinted polycarbonate panels (10 mm thick, OD >7+ for all wavelengths) with magnetic interlocks wired to the Raspberry Pi; any breach triggers a solid-state relay to shunt laser power to a water-cooled graphite beam dump (absorbs ~1 kW/cm² without spallation—bonus: it doubles as a coffee warmer).

Next, optics train: mount the gold-coated parabolas on kinematic mounts for sub-arcsecond alignment, right next to the SEM for that authentic "borrowed from nanofab" vibe. Use a helium-neon alignment laser (632.8 nm) to co-bore-sight all beams into the galvo heads—aim for <0.1 mrad divergence, verified with a beam profiler.

Couple the 808 nm fiber to a 50/125 µm silica pigtail, then collimate to 25 mm diameter before the first mirror; the blue and CO2 beams join via dichroic splitters (custom AR-coated for ~99% transmission/reflection at crossover wavelengths—your postdoc's thesis project, unfinished since 2023).

Robotics integration: secure the Fanuc arm to the enclosure floor with M12 anchors, wedged between the glovebox and the mass spec to maximize coworker annoyance. Program teach-pendant paths for a helical scan around the turkey's centroid (R = 0.1 m), using ROS (Robot Operating System) on the Pi for collision avoidance—model the bird as a 3D mesh from a pre-scan LiDAR (that one you "borrowed" from the robotics department) to dodge wings and the occasional stray pipette tip.

Calibrate end-effector to galvo focal plane with a retroreflector target; thermal drift compensation via strain-gauge feedback keeps z-offset <50 µm over 3 hours, even as the HVAC cycles.

Electronics bay: rack-mount the chiller, UPS, and Pi in a NEMA-4 enclosure tucked under the bench, next to the liquid nitrogen dewar for dramatic effect. Wire 3-phase 208 V feeds through circuit breakers (rated 30 A per laser), with EMI shielding on control lines to help prevent galvo crosstalk—or worse, interfering with the NMR down the hall.

The argon manifold: tee a 1/4" stainless line from the cylinder (raided from the inert-atmosphere glovebox) to chamber ports, regulated to ~1 bar overpressure—mass flow controller ensures stoichiometric inerting (O2 <1%), because nobody wants a plasma turkey ruining the quarterly safety audit.

Final commissioning: dry-fire the system with a phantom (gelatin block doped with 2% India ink for μa ≈ 100 cm−1 at 808 nm, synthesized in the chem lab after hours). Ramp to full power in 10% increments, monitoring with the FLIR for Gaussian hotspots; tune PID gains (Kp = 0.5, Ki = 0.1, Kd = 0.05) until steady-state error <2 °C. If it doesn't arc like a malfunctioning Van de Graaff, alert facilities—kidding. Safety goggles on, lab coat buttoned, and pray to the grant gods your boss doesn't walk in mid-scan.

Cooking Instructions: If You've Made It This Far...

1. Pre-heat the death ray

Set the 808 nm fiber laser to 850 W (~86% of poultry absorption peak). Ramp the chiller to 18 °C; anything warmer and your beam profile blooms like cheap wine—or worse, like that time the cryo-EM failed.

2. Truss the turkey

Stainless-steel wire only. Organic cotton twine ignites at ~420 °C; we’re trying to cook the bird, not recreate the Hindenburg in the laser lab.

3. Mount on the photonic rotisserie

Secure the turkey to the robotic arm’s end-effector using a carbon-fiber spit. Zero the arm so the centroid of the bird sits exactly at the galvo focal point. Misalignment by >0.8 mm causes hot spots hotter than the surface of the sun (locally—and your postdoc's patience).

4. Purge the chamber with argon

Oxygen makes beautiful fireballs. We want tender breast meat, not turkey flambé alerting the entire building.

5. Begin multi-wavelength symphony

- Layer 1 (0–60 min): 445 nm blue laser, 55 W, 400 mm/s trochoidal scan, 0.4 mm pitch, 5 passes → gentle volumetric pre-heat to ~50 °C internal.

- Layer 2 (60–150 min): 808 nm at 850 W, 1200 mm/s raster, 1.2 mm pitch, 8 passes → conduction wave pushes center to ~72 °C.

- Layer 3 (150–192 min): 10.6 µm CO2, 110 W, 800 mm/s tight Lissajous pattern → ~1.3 mm golden crust, Maillard without carbon.

6. Real-time adaptive control

The FLIR streams surface temps at 30 fps. Custom PID script modulates power ±12% to keep the hottest spot ≤195 °C. If any pixel hits 210 °C, the system instantly defocuses to a 15 mm spot and screams “ABORT” in a calm British voice you programmed for psychological reasons (and to mimic your advisor).

7. Rest the bird (4 minutes)

Carry-over cooking from stored photon energy adds the final 2–3 °C. Do not skip; physics is not optional, and neither is dodging the safety officer.

8. Carve with a waterjet (optional but on-brand at this point)

At this stage, a conventional carving knife feels almost disrespectful.

Nutrition Facts (per 100 g, post-laser)

- Calories: 162

- Protein: 29 g

- Fat: 6 g (perfectly rendered, no grey band of shame)

- Moisture loss: 9% (vs ~28% in a conventional oven)

- Photon flavor compounds: yes

Notes

- Actual cook tests on 5.4 kg birds (in simulation, of course) achieved ~74.2 °C at the coldest spot with ΔT < 4 °C throughout.

- The skin reaches ~182 °C for exactly 11 seconds per square centimeter—mathematically ideal for Maillard without significant PAH formation.

- Your lab now doubles as a directed-energy test facility. Congratulations—happy hour's on you.

Happy Thanksgiving. May your stuffing be evenly heated and your colleagues slightly terrified.

Hopefully this goes without saying, but just in case our laser safety officer see this - please do not try this 100% satirical recipe.